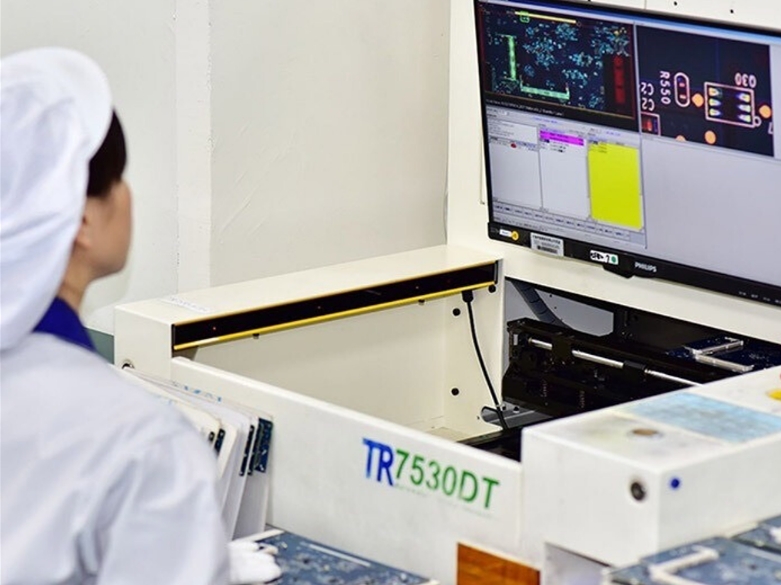

Test & Inspection

Rigorous PCB Testing for Quality and Reliability

At DMax, we emphasize the importance of rigorous testing to ensure every product meets the highest standards of quality before leaving our facility. Our testing process includes various stages designed to check functionality, reliability, and mechanical integrity:

-

Functionality Testing

Verifies that the product performs as expected and meets all specified requirements.

-

Reliability Testing

Ensures that the product will maintain performance under various conditions, such as temperature, humidity, and vibration.

-

Mechanical Testing

Assesses the physical robustness of the product, including stress testing, bending, and durability under mechanical loads.

Devices & Technologies

We utilize cutting-edge equipment and advanced techniques to perform precise testing and inspection, ensuring high-quality standards:

-

Automated Optical Inspection (AOI)

Used for inspecting the quality of SMT assemblies, detecting any defects such as missing components or misplacements.

-

Dage X-Ray XD-7500

Provides in-depth X-ray inspection to identify hidden defects in solder joints, particularly in BGA (Ball Grid Array) and complex multilayer PCBs.

-

Auto Printer

Ensures the correct and uniform application of solder paste during the assembly process.

-

BGA Rework Station

For precise rework of BGA components, ensuring high-quality solder joints and functionality.

-

200X Magnification Microscope

Provides detailed inspection capabilities to detect fine defects on the PCB surface.

-

PCB Separator Cut Machine

Used for separating individual PCBs from panelized units with precision.

Quality Assurance

Our commitment to quality is evident at every stage of production, with a detailed and structured approach to ensure that every product meets the required standards:

-

In-Depth Inspections

Every product undergoes comprehensive inspection, including visual checks, automated testing, and functional evaluations.

-

First Article Inspection

The first units produced in a batch are thoroughly tested to ensure they meet specifications before full-scale production begins.

-

Continuous Debugging and Troubleshooting

Any issues identified during production are addressed promptly through debugging and troubleshooting, ensuring optimal functionality.

Production Flowchart for Quality Assurance

To maintain the highest level of quality, we follow a meticulous production flow:

-

01

Material Preparation

Incoming inspection

Labeling and recording part numbers (PN)

Sample confirmation

Stencil creation

DIP carrier creation

Standard Operating Procedure (SOP) generation

-

02

SMT

(Surface Mount Technology)Check Bill of Materials (BOM), PnP files, and Gerber files

Setup SMT machine and AOI program

Load parts into SMT feeders

Perform first article inspection

Debug and troubleshoot issues

-

03

DIP

(Dual In-line Package)Check for parts that cannot pass wave soldering

Preprocess materials

Insert parts into PTH (Plated Through Holes)

Perform wave soldering and manual soldering

Conduct first article inspection

Debug and troubleshoot issues

-

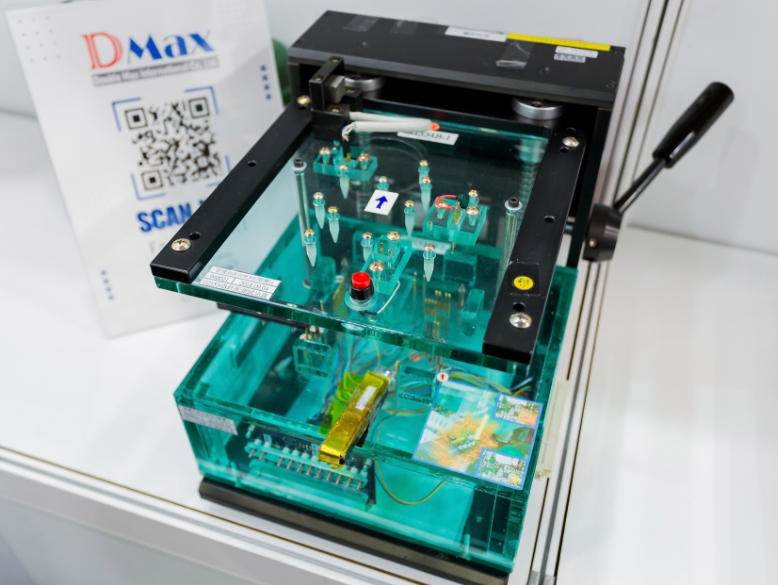

04

Test &

Mechanism AssemblyGenerate test and assembly SOP according to customer instructions

Set up testing stations (tools and fixtures)

Perform first article test

Debug and troubleshoot issues

Advantages

-

High Precision

Our testing processes and equipment ensure precise inspection, enabling us to identify even the smallest defects that could affect product performance.

-

Automated and Manual Inspection

Combining automated optical inspection with manual checks ensures thoroughness and reliability at every stage of production.

-

Comprehensive Inspection Flow

Provides in-depth X-ray inspection to identify hidden defects in solder joints, particularly in BGA (Ball Grid Array) and complex multilayer PCBs.

-

Continuous Debugging

Any issues that arise during production are promptly addressed, guaranteeing that only high-quality products reach the customer.

At DMax, our pursuit of perfect quality means that every product is carefully tested, inspected, and verified, ensuring reliability and performance before it leaves our production line.

Contact US