Applications

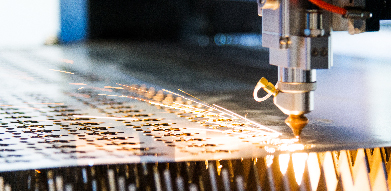

CNC Machine

To improve efficiency and remote management on the CNC shop floor, industrial networking is required from both device level and infrastructure level. Implementing an industrial serial device server can replace the front-end PC, eliminate manual monitoring

processes, and provide remote management. A Virtual COM Driver, provided with most serial device servers today, can provide continued use of existing application software found on the shop floor.

Machine Vision

The latest generation of machine vision systems offers significant improvements by incorporating industrial Ethernet switches and other Ethernet devices. This enables direct communication between PLCs, robot controllers, PCs, and human machine interfaces

(HMIs). However, there is still serial-based equipment, such as sensors, readers, cameras, and vision systems, that cannot be easily networked.

Food and Beverage

Nowadays equipment suppliers are providing new Ethernet-based equipment and IP based application software and no longer provide further support for legacy serial-based devices. With this mixture of serial and Ethernet based equipment, it is difficult to

monitor production processes. A serial-to-Ethernet device server can provide Real COM drivers or socket tunneling for legacy equipment connection in TCP/IP format. A reliable Ethernet network has become a critical part of a bottling plant’s infrastructure,

due to harsh environments. Industrial managed Ethernet switches with fiber-optic solutions can be used to overcome this concern, because of their reliability, long lasting industrial grade design, and data transmission immunity. Layer 2 managed switches with

data routing software can also increase the determinism of a bottling plant’s control network. A built-in ring redundancy feature eliminates any downtime concerns, and event handling software functions can send out alert emails to improve real-time monitoring

and management.

Material Handling

It is critical for manufacturers to implement a proficient network, because most material handling systems, machines, and equipment come with mixed communication interfaces, stand-alone processes, and are not efficiently networked. For example, AS/RS systems

rely on a networked front-end computer terminal for status reports, and it is difficult for a control room to monitor field device status if downtime occurs. A serial-to-Ethernet device server can be networked instantly with field legacy equipment to improve

the efficiency and real-time monitoring. Due to the scope of the material handling facility, PoE or IP-based video cameras can be networked for safety and real-time process monitoring. Network downtime is also a major concern for process data exchange. A redundant

ring network provides fast network recovery if any unexpected link failure occurs.

Process Automation

Each local process section in the pulp & paper industry is still integrated with a large amount of legacy serial-based equipment that is unequipped for an Ethernet network. In order to provide networking capability, an industrial serial device server can

convert serial data into TCP/IP data to transmit through the Ethernet network.

Agriculture Technology

Antaira’s M12 series of industrial switches do all of the below, as well as provide dust and water tight connections allowing the industrial Ethernet switch to be mounted in places where few other devices would survive. While this solution would run all

on its own, a wireless radio can be added to the solution to transmit the general health of the vehicle when it returns to the barn for refueling or recharging.

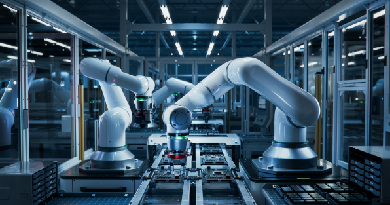

Assembly Line

Machine Vision is becoming much more critical in automation applications, especially where robotics is involved. GigE Vision is a global standard communication protocol that has been adopted by machine vision camera manufacturers. While GigE Vision allows

for faster image transfers using standard cabling, the bandwidth requirements are significantly greater than previous generations of machine vision cameras. In addition, in order to simplify wiring, many GigE Vision cameras will use PoE for power so only one

cable needs to be run. Aggregating multiple GigE Vision cameras into one link into the Industrial PC (IPC) will often require a 10G link from the PoE switch to the IPC running the software.

Case Studies

South Korea

Transformation to Automated Assembly Factories

Industry 4.0 is currently at the forefront of industrial transformation, seamlessly integrating networking, IIoT and automated production.

U.S.A

Optimizing Weed Control with Revolutionized Agricultural Technology

A US agricultural company utilizing fully automated farming equipment designs machines to include the use of high-speed GigE vision cameras and insecticide sprayers combined with Artificial Intelligence allowing for a machine to determine if a plant is

a weed, and dispose of it in a flash.