Applications

Water Treatment Process

Waste water treatment plants can be extremely large in size and can geographically cover hundreds of acres of land. A wastewater treatment plant covers several different process areas that include bar screens, grit chambers, multiple clarifiers, aeration

tanks, bio solids, and disinfection. After water leaves the waste water treatment plant, it can be used for ground water replenishment, irrigation or further treatment at a water purification plant for human consumption.

Remote Pump Station Monitoring

Maintenance and troubleshooting of pumping stations can be challenging and time consuming as these premises are classified as confined space and often located in remote areas. A rugged industrial Ethernet device networking solution setup is critical in

order to efficiently monitor and control the remote pump station’s water flow, pressure levels and potential leak issues in real time. Industrial networking equipment can also provide built-in advanced event handling software features to report alarms in real-time

via text message or email, and immediately notify on call technicians as well as any of the customer’s staff of emergency and non-emergency occurrences.

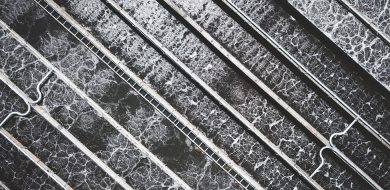

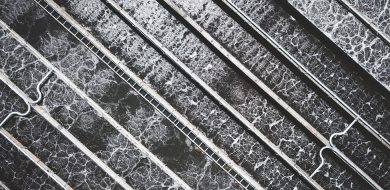

Water Pipeline Monitoring

Water is without a doubt the most precious resource in the world. Monitoring of the nation’s water transportation infrastructure is of vital importance for consumption, food production and power generation. Due to the massive and rugged geographical areas

water pipelines traverse, direct human inspection of this water transportation system is challenging. Therefore, equipment such as flow meters, pressure gauges, vibration and moisture detectors are utilized for monitoring of our water supply. Monitoring stations

placed along the water pipeline can provide remote access and surveying of larger geographical areas by fewer individuals. Data received from the monitoring equipment in the field can allow for better allocation of maintenance and service personnel. With more

real-time information at the disposal of the command center team the whole system is able to operate more efficiently with less downtime.

Water Resources Management

Dams require an extensive amount of monitoring and control data that provide critical information to keep things running efficiently and reliably. Monitoring is performed for both security and safety reasons around the outside perimeter, input channel,

spillway and inside the dam itself. The local administration center is responsible for collecting, monitoring and controlling information related to water intake, distribution and even power generation in hydroelectric dams. The equipment that provides information

to the control center can have different communication mediums such as serial, Ethernet, fiber optics or wireless. Due to the average age of dam infrastructures, it is not unusual for serial equipment to still be found. However, it is imperative that data

communication be resistant to electronic noise interference generated from large motors, turbines and power. Fiber optic cables are immune to electronic noise and are an ideal solution in providing fast, reliable uninterrupted data communication. Fiber optics

are also ideal for providing long distance communication to off sight administration centers.