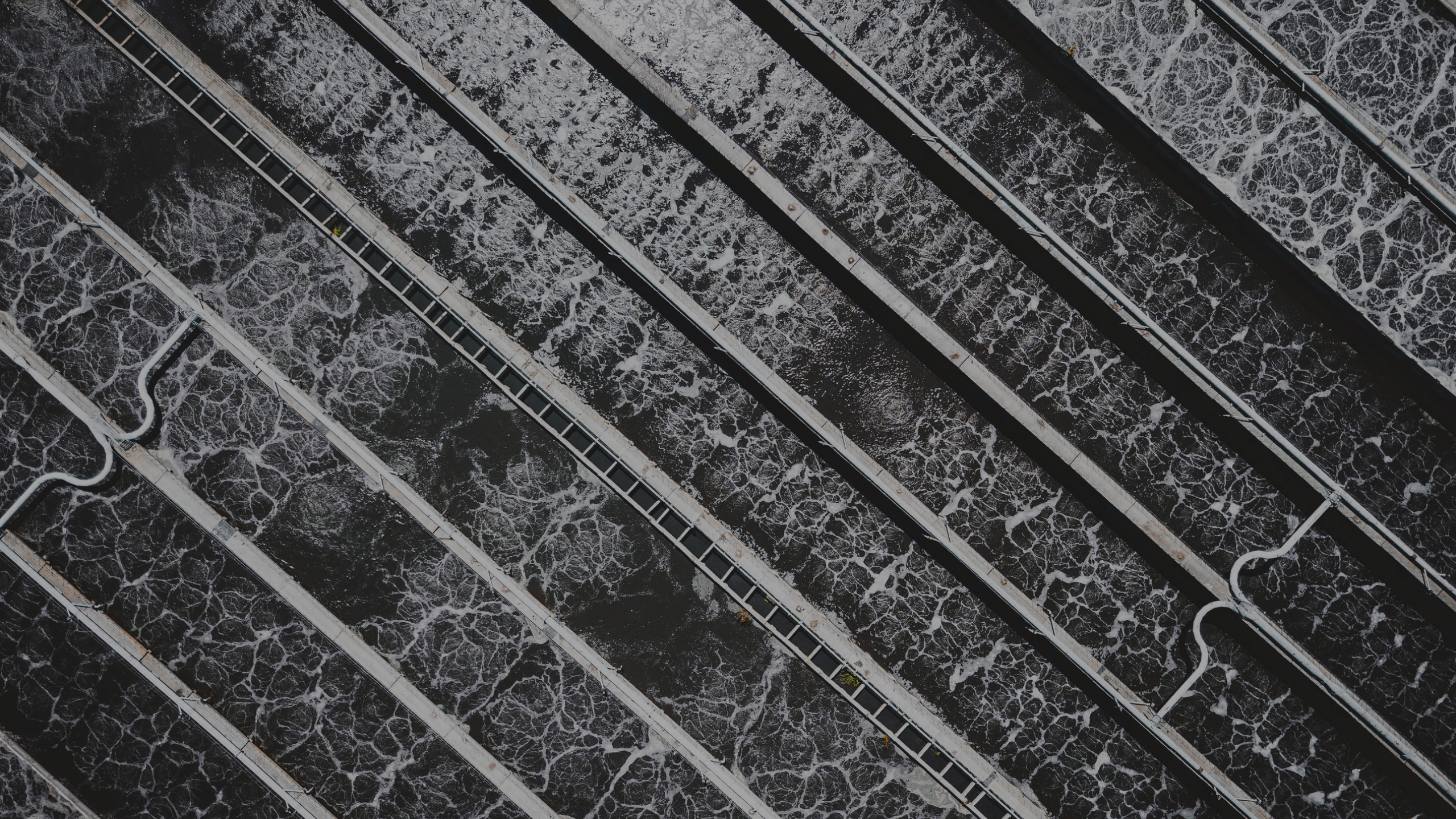

Waste water treatment plants can be extremely large in size and can geographically cover hundreds of acres of land. A wastewater treatment plant covers several different process areas that include bar screens, grit chambers, multiple clarifiers, aeration tanks, bio solids, and disinfection. After water leaves the waste water treatment plant, it can be used for ground water replenishment, irrigation or further treatment at a water purification plant for human consumption.

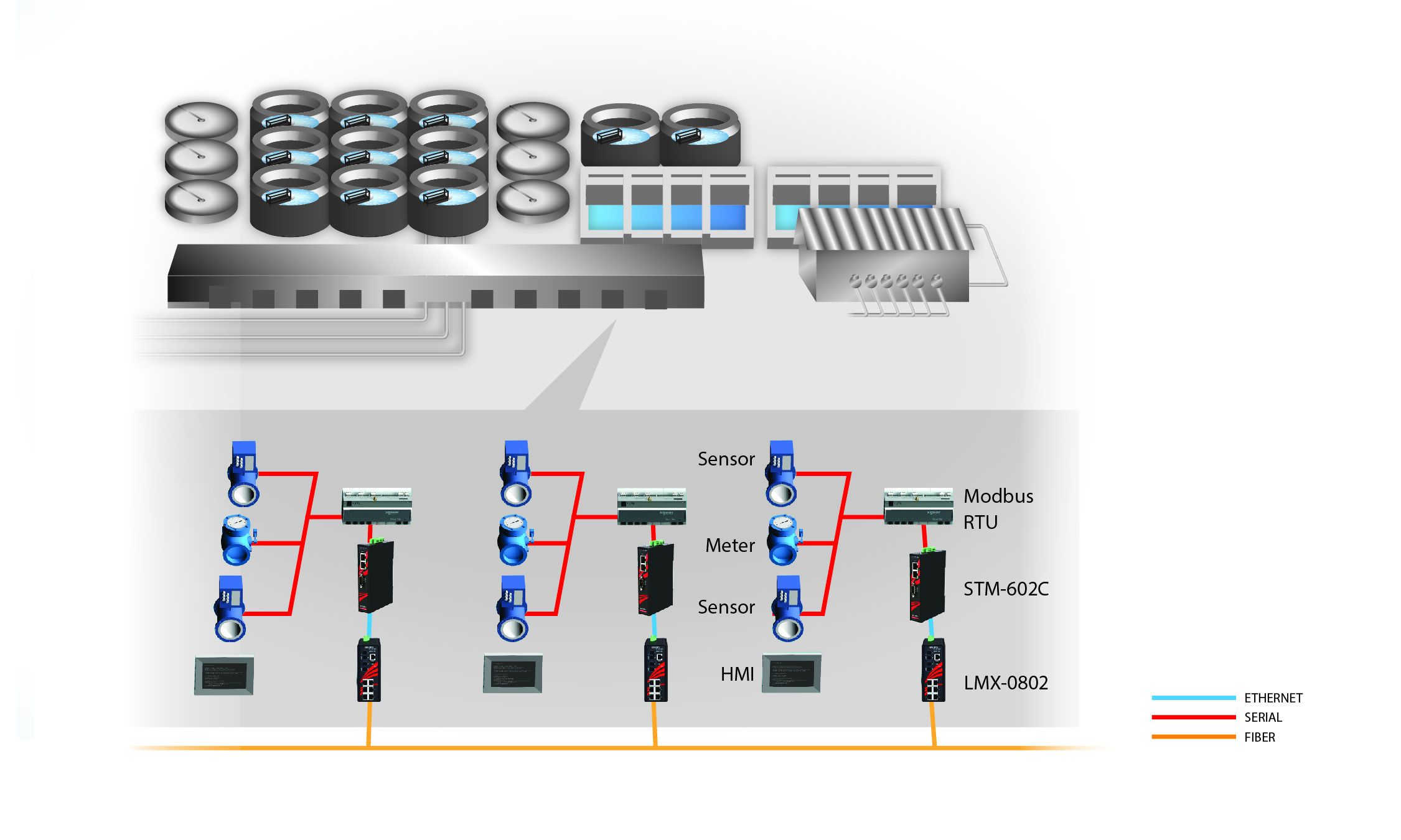

The control and management of this water is a complex task requiring thousands of measurement devices to provide constant data to various locations. Because of the large quantity of devices and the standardization that IEEE compliant devices offer, Ethernet is used as the communication standard around the plant site. A reliable Ethernet network within the waste water treatment plant is required in order to receive and provide constant and accurate data. Equipment redundancy is required for all steps within the water treatment process. The same should be done with the communication network and can be by utilizing a redundant network topology such as STP, RSTP or ERPS G.8032 standards.

Adopting an Ethernet network gives water treatment plants an efficient data collection and management infrastructure for seamless upgrades and future expansion that is required for today’s growing cities. High-speed fiber backbones can not only help utilities to collect data from remote locations within the water treatment plant but fiber optic cable is also immune to electric noise from large equipment and power generation found in many areas of plant site.

As treatment plants continue to upgrade, serial communication equipment or measurement equipment that require a serial connection are still being utilized. Serial device servers can be utilized to convert this serial data to Ethernet data, therefore allowing treatment plants to utilize their older equipment but still connect to the network.

- Harsh environment with temperature and humidity challenges

- Large geographical area

- Heavy equipment usage

- Zero down time with 24/7 usage

- Different communication standards

- Advanced monitoring and management control

- Industrial grade networking devices to perform under harsh environments

- Capability to connect legacy serial devices to the TCP/IP network

- Fiber optics for long distance communication

- Reliable data routing with built-in network management software

- Self-healing redundant network support

- Shock & vibration resilience

- High MTBF and wide temperature range support