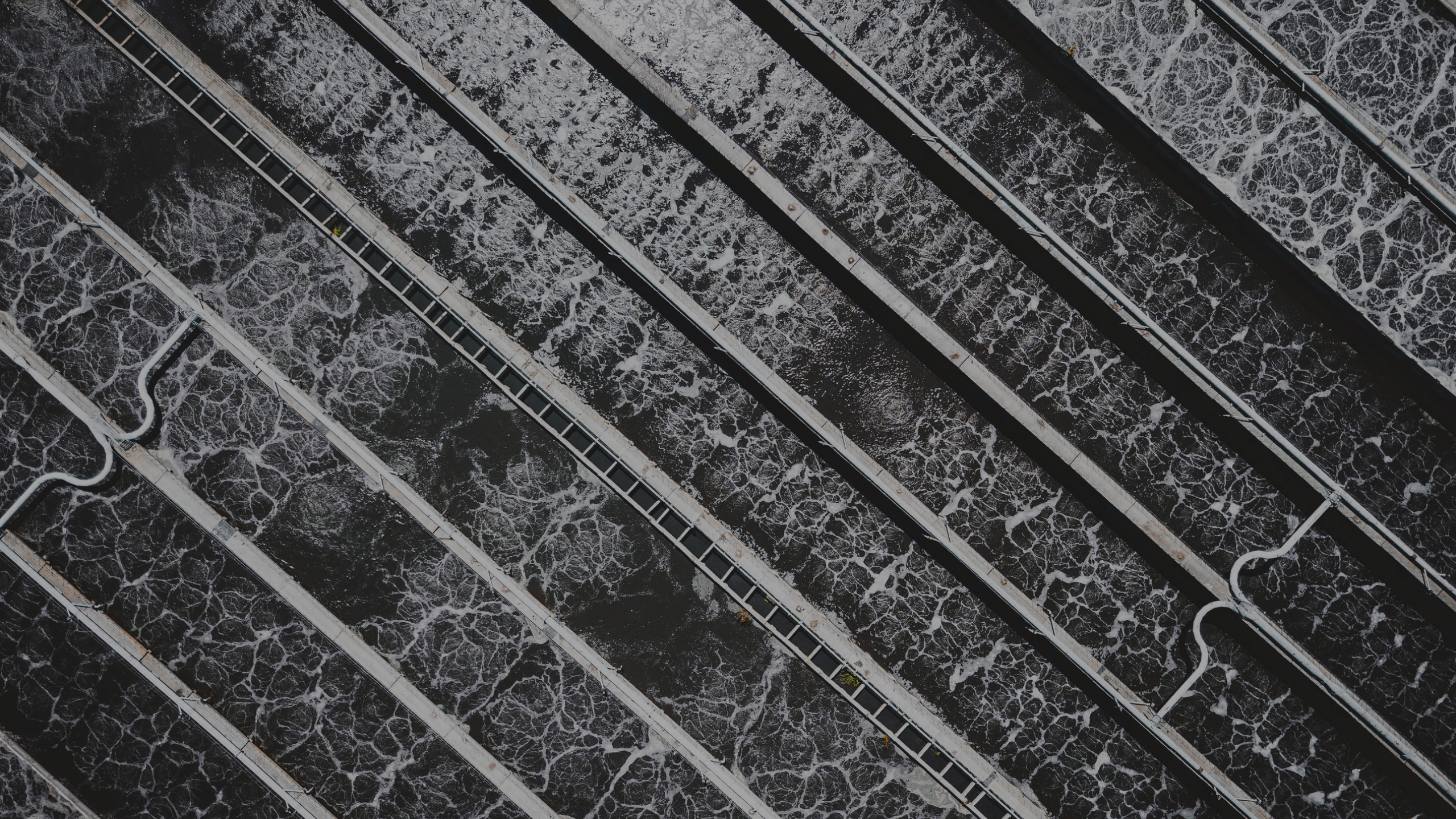

Maintenance and troubleshooting of pumping stations can be challenging and time consuming as these premises are classified as confined space and often located in remote areas. A rugged industrial Ethernet device networking solution setup is critical in order to efficiently monitor and control the remote pump station’s water flow, pressure levels and potential leak issues in real time. Industrial networking equipment can also provide built-in advanced event handling software features to report alarms in real-time via text message or email, and immediately notify on call technicians as well as any of the customer’s staff of emergency and non-emergency occurrences.

In the past, local service engineers were called out to visit unmanned pumping stations to check the status and determine if any problems had occurred. By implementing an industrial device network to a remote pumping station, the control system status can be read and analyzed before sending a service engineer to investigate.

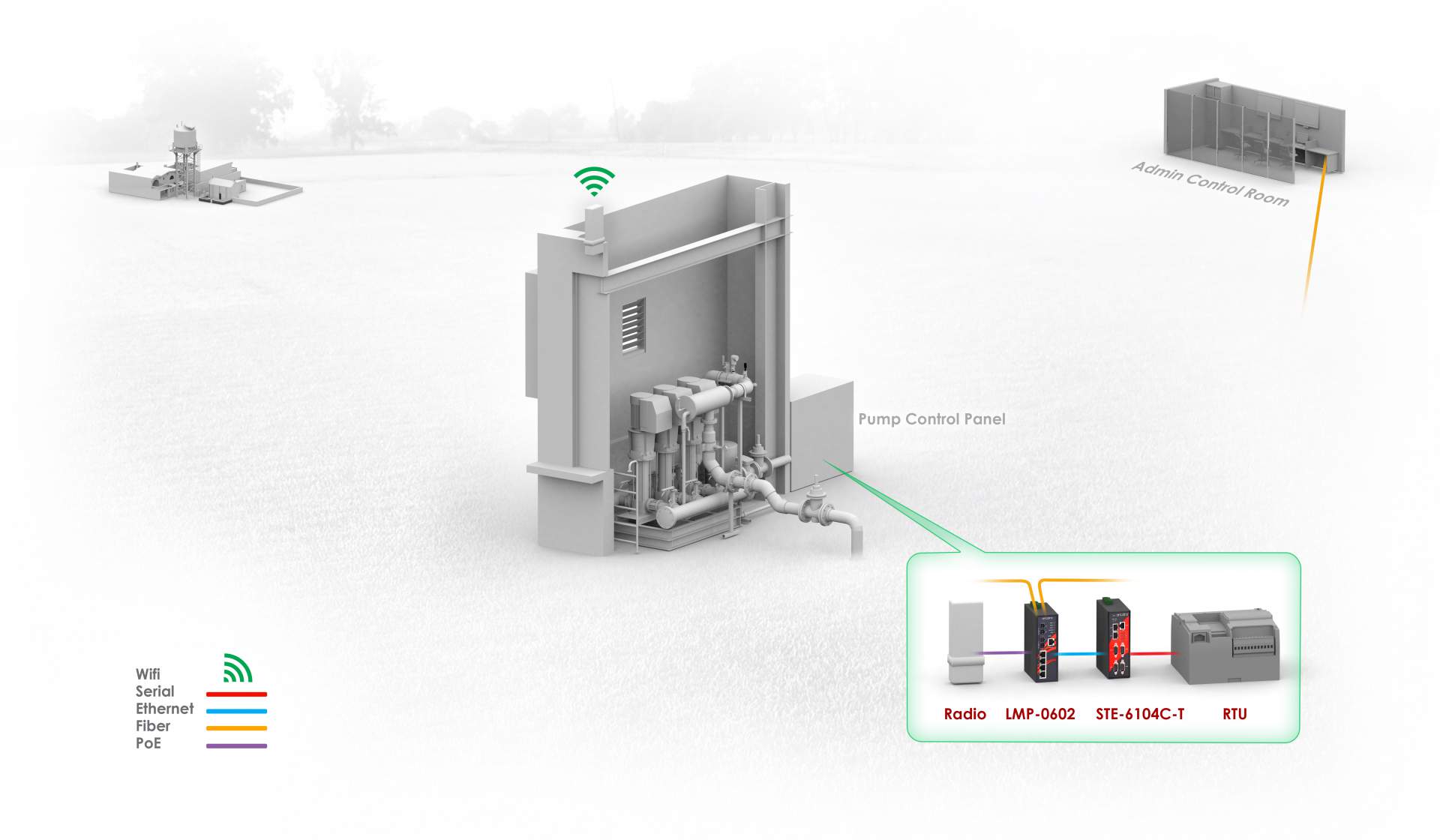

- Remote field site contains extreme ambient weather concerns

- Real-time data transmission between the pumping station and control center

- High MTBF network equipment to ensure reliability

- Ability to transmit data over long distances

- Industrial grade networking devices to perform under harsh environments

- Capability to connect existing devices to the TCP/IP network

- Reliable data routing with built-in network management software

- Shock & vibration resilience

- High MTBF and wide temperature range support

- Enable integration of video surveillance systems